Contact Info

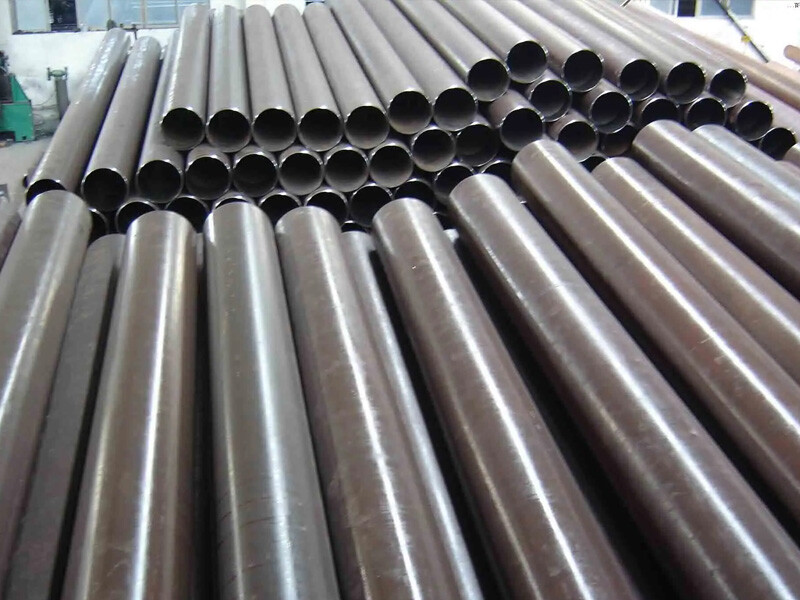

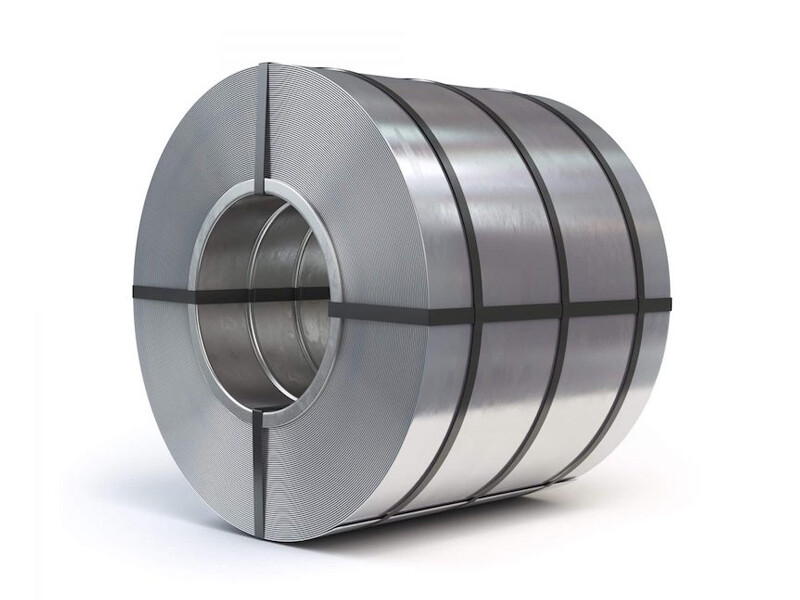

Packaging and loading:

Packaging: According to customers' needs, use wrapping paper. If the transportation period exceeds 10 days or encounters special climate, we will use waterproof packaging and add plastic film to prevent moisture, water and rust.

Loading: We use the wooden pallet,triangular wood to fix the coil,and the steel wire rope to hold on the both side. That can prevent from the crush injury effectively.

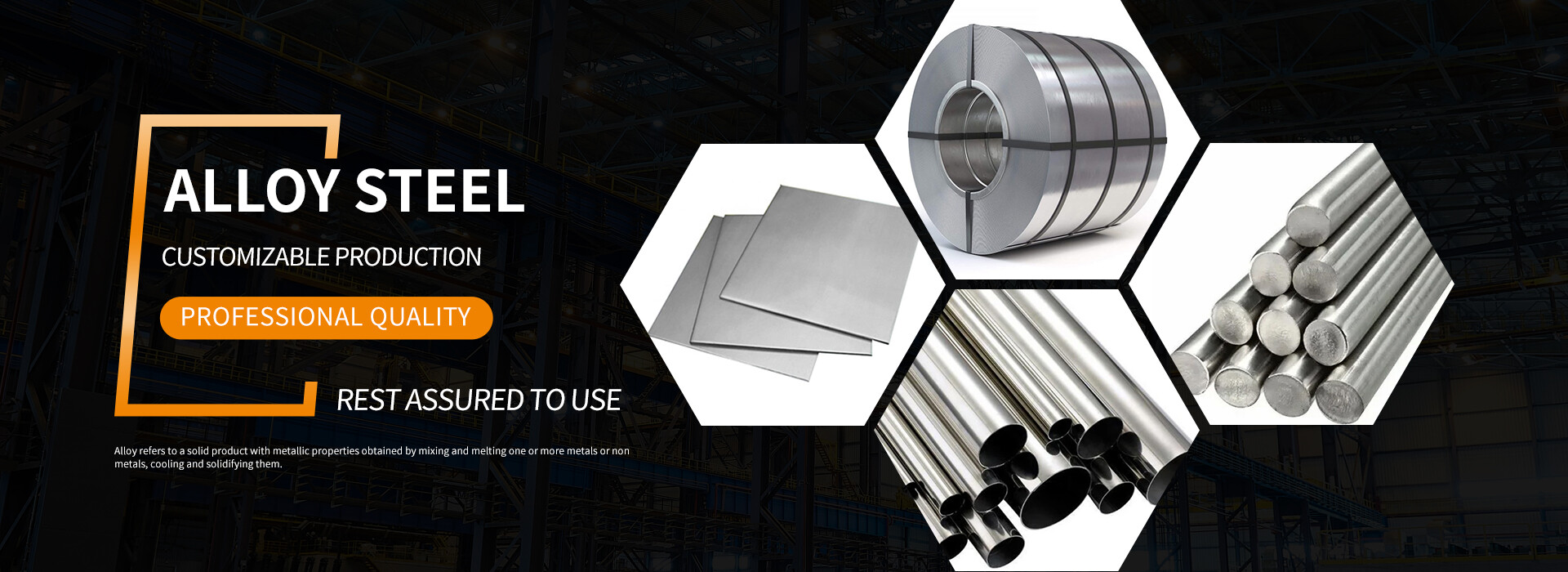

Key products such as stainless steel, carbon steel, copper, aluminum, and alloys have entered key industries such as petroleum, petrochemicals, railways, automobiles, shipbuilding, containers, and coinage, and are applied in key fields such as high-speed rail, sports venues, and nuclear power. Its rapid and stable development cannot be achieved without the company's high-quality talent team and advanced management model. At the same time, in the spirit of "quality survival, innovative development", we strive to strive for excellence in every detail, achieving a win-win situation for both the company's interests and customer interests. The company is committed to building a resource saving and environmentally friendly modern enterprise, and is committed to building a world-class, high-quality research and development and production base for stainless steel and special alloy materials, becoming the first choice for customers.

FAQ

Q1:Accepted delivery terms

A1:EXW, FOB, CFR, CIF, FCA, FSA, CPT, CIP, DAT, DAP, DDP, DDU

Q2:Accepted Payment Types

A2:T/T, L/C

Q3:What is your delivery time ?

A3:8000 tons of inventory guarantee immediate delivery, Non-stock products, delivery within 5-7 days.

Q4:Accepted payment currencies

A4:CNY, USD, EUR, JPY, CAD, AUD, HKD, GBP, CHF

Q5:What standard steel can you provide?

A5:We can provide various standards, such as: AISI, ASTM, ANSI, ASME, UNS, SAE, DIN, EN, GB, JIS, etc

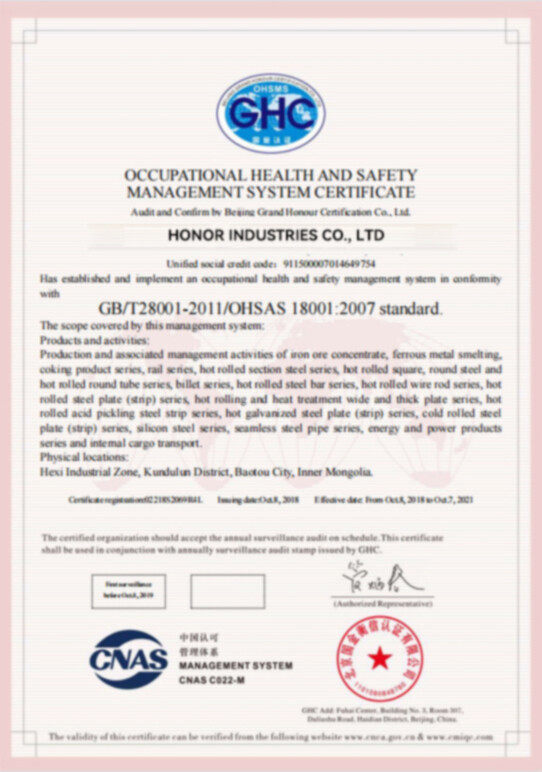

Q6:How do you guarantee the product quality?

A6:CE, ISO certificate, supporting any third party inspection. A pre-production sample before mass production, final Inspection before shipment.

Related Suggestion

Online Consultation